Drive shaft for Ford 8.8 swap

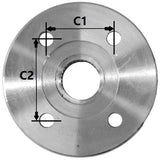

Ford 8.8 axles are a common upgrade for the Jeep YJ, TJ, and XJ. Most people who do the 8.8 swap will tell us that they already have the "adapter". The so-called adapter is what we would call a flange yoke and is something that should be treated as part of the drive shaft. Here's why. The drive shaft needs to be built and balanced as a complete assembly, with all drive shaft parts installed. If you add parts to the shaft after it is balanced, you will likely have a high speed vibration problem. This could be because the flange yoke is slightly heavier on one side than the other, or that it is machined slightly off-center which in turn puts the entire drive shaft off-center, thus causing a vibration. We can and do build drive shafts for 8.8 swaps that include the correct flange yoke. Your Ford 8.8 pinion flange might have one of two bolt patterns, measure what you have and select the correct option in the drop down menu. If you have questions about any of this, give us a call!

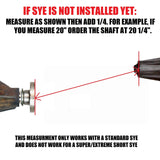

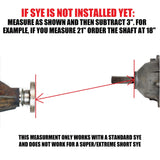

Shaft will require a slip yoke eliminator.

- Will bolt directly to your 8.8 pinion flange.

- Bolts to 1310 series yoke on transfer case.

- 2" diameter .120 wall USA made DOM tube.

- Bigger and stronger than stock spline stub.

- Forged slip yoke.

- Greaseable CV center ball.

- Your choice between Tom Wood's exclusive Gold Seal greaseable universal joints or non-greaseable joints.

- Your choice of spine and slip yoke options, more on that here. Shafts shorter than 17 3/4" are too long for the X spline, you will need to select the S spline option.

- Comes with new CV bolts with reduced head for ease of installation.

- Best of all every shaft is custom built to whatever length you need. So you can be sure that you will get the right thing the first time around.

Just make sure you measure the length and the bolt pattern as shown in the product photos. THERE ARE TWO PRE-SYE MEASURMENT PHOTOS, USE THE ONE THAT MATCHES YOUR VERSION OF THE 231 TRANSFER CASE.