TJ Rubicon Front Drive Shaft

Front drive shaft for Jeep TJ or LJ Rubicon. Only fits Rubicon model. The difference between a Rubicon and standard TJ is that the Rubicon uses 1330 series joints and components.

TJ Rubicon front drive shaft replacement is a good idea for almost any TJ Rubicon that is still running a stock drive shaft. TJ Rubicon stock front drive shafts used fairly low grade components. Add a lift, bigger tires, and 14+ years of wear and tear and the result could be badly worn or even worse a broken stock drive shaft. Tom Wood's TJ Rubicon drive shafts are built using only the highest quality components. Key features listed below.

- 2" diameter 0.120" wall USA made DOM tube.

- 1330 series joints.

- Bigger and stronger than stock spline stub.

- Forged slip yoke.

- Greaseable CV center ball.

- Your choice between Tom Wood's exclusive Gold Seal greaseable universal joints or non-greaseable joints.

- Your choice of spline and slip yoke options, more about that here.

- Comes with new CV bolts with reduced head for ease of installation.

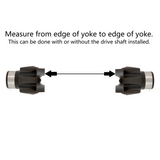

- Best of all every shaft is custom built to whatever length you need. So you can be sure that you will get the right thing the first time around.

We recommend a new set of straps and bolts to securely attach your new drive shaft.