Jeep Cherokee Multiple Double Cardan Front Drive Shaft

For Jeep Cherokee, XJ. The multiple double cardan shaft is a shaft with a double cardan (aka CV) on each end of the shaft. This is used when proper geometry for a conventional double cardan cannot be achieved due to lift height or other reasons. This is usually the case on vehicles with more than 4 inches of lift. The multiple double cardan is only recommended if you have a big lift, bad angles, and the drive shaft is spinning all the time. It is also only applicable to front drive shafts. For a better understanding of all this you can watch the video embedded at the bottom of this page.

Key features listed below.

- Includes required double cardan compatible yoke for front axle.

- 2" diameter 0.120" wall USA made DOM tube.

- 1310 series joints.

- Bigger and stronger than stock spline stub.

- Forged slip yoke.

- Greaseable CV center ball.

- Your choice between Tom Wood's exclusive Gold Seal greaseable universal joints or non-greaseable joints

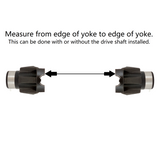

- Best of all every shaft can be custom built to whatever length you need. So you can be sure that you will get the right thing the first time around.