Measure as shown on this page, then call us with your measurements for more information or to place an order.

📞 Call to Order: (801) 737-0757Mon–Fri 8:00 – 5:00 MT

The front shaft in Toyotas with solid axle swaps (SAS) or highly flexible leaf springs can get a bit complicated. These types of suspension setups in Toyotas create a couple of problems, problems with angles and with compression/extension. The compression/extension issue is why you’ll see guys running square tube drive shafts, because they otherwise pull apart and separate their stock slip yoke. To build a shaft for SAS Toyotas and many Toyotas with OEM solid axles on a leaf spring front suspension we will need a lot of measurements. You can watch a short video showing how to measure these things here https://www.youtube.com/watch?v=W6PwSW4x9_E&t=1s A list of required measurements can be found below.

Frankly, there's a couple things you may not like about the type of shaft required for this application. Most of the time, depending on angles and compression/extension numbers, we need to build the shaft with two special features. One feature, which is usually required due to the operating angle at the transfer case end of the shaft, is our high angle "Superflex" joint. This joint basically makes the drive shaft wobble, which will cause added vibrations. The other special feature is that due to extreme amounts of compression and extension we usually have to build the shaft using our "Ultimate Travel" spline. This type of spline is physically heavier than, and does not fit together as snugly as, a more conventional type spline. These factors will also contribute to increased vibrations, though not as much as the superflex joint does. Both the superflex joint and the ultimate travel spline mean that these shafts are meant of low-speed off-road use only, and are not approved for high speed or normal road use. Which means that when not off-road the shaft will need to be disengaged by unlocking your hubs and shifting your transfer case into 2WD. Much of the info in this paragraph is not ideal and not what SAS Toyota owners want to hear but it is unfortunately the reality of these highly modified vehicles. Things that alleviate some of the problems, which might enable us to build a shaft that works better at higher speeds, are high pinion axles, dual transfer cases, or running coil springs instead of leaf springs. The possibility for all these different variables are exactly why we need to get so many measurements before building the shaft.

Usually, these shafts end up costing just over $580. Here’s a list of the measurements we’ll need. Once you have the measurements give us a call if you’d like to order a shaft.

Required Measurements:

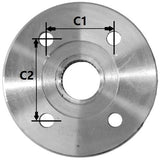

T-case flange pattern:

C1=

C2=

Axle flange pattern:

C1=

C2=

At static ride height:

Length face of flange to face of flange=

Slope of driveshaft=

Slope of T-case=

Slope of Diff=

At full Droop (with front suspension fully extended):

Length face of flange to face of flange=

Slope of driveshaft=