Measuring Your XJ Cherokee Driveshafts

XJ Cherokee Front Drive Shafts

Jeep XJ drive shaft lengths vary a bit and we want to make sure you get the right thing. That is why we require a length measurement before building the shaft. Measuring is simple and easy. You can read more about how to measure below.

XJ Front Drive Shaft Length

Conventional Double Cardan Drive Shaft

Go to XJ Front Drive Shaft product page.

Multiple Double Cardan Shaft

If you have more than 4" of lift, our multiple double cardan drive shaft may be your best choice (four U-joints). This drive shaft can only be built with our S spline. The cost for this shaft is $619. The required pinion yoke is $85. The multiple double cardan shaft must be ordered over the phone.

XJ Cherokee Rear Drive Shafts

Stock type rear shaft

We can build a new stock type drive shaft for your Cherokee. We will need the length measurement taken from the vehicle with the drive shaft removed and the vehicle resting on the ground.

Go to Stock XJ Rear Drive Shaft product page.

We also need to verify U-joint size at the differential end.

Double Cardan Rear Shaft

If you have substantial lift and want smooth operation out of your shaft, we suggest one of the Slip Yoke Eliminator (SYE) kits along with a double cardan (CV) drive shaft.

Go to XJ Double Cardan Rear Drive Shaft product page.

With this system eliminates the need for any transfer case drop spacers. You may need to rotate your differential so the pinion points directly at the out-put of the transfer case to maintain minimal joint angle at the differential end.

If you will measure the slope of the drive shaft and the slope of the pinion, we can calculate any adjustment that may be needed. With leaf spring suspension, this is easily corrected with shims placed between the springs and spring perch. If you have coil springs, the adjustment is made with either cam bolts or adjustable control arms.

XJ Slip Yoke Eliminator options

Before purchasing an SYE. You may need to identify which transfer case you have. This is easily done by looking at the ID tag on the back of the transfer case.

How To Identify Which Transfer Case You Have

You should identify the model of the transfer case by looking at the top line of the ID tag. It will say something like NP231 or NV242J.

We have Slip Yoke Eliminator kits for both the 231 and 242 transfer cases.

XJ Rear Drive Shaft Length

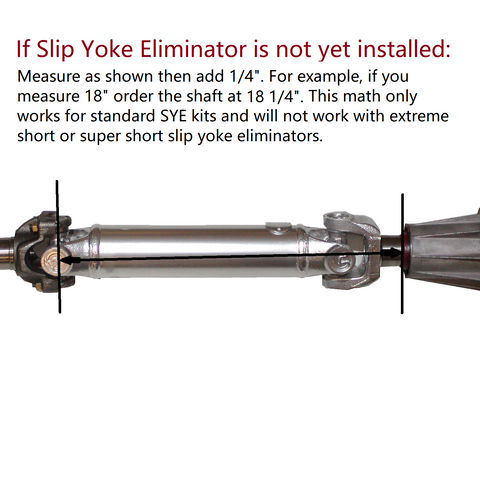

If you already have a Slip Yoke Eliminator kit installed, measure as shown above for the XJ front drive shaft. If you don't have one installed yet and want to order the SYE and drive shaft all at once, measure as shown one of the examples below.

Late model transfer cases (usually1995 and newer)

If you have a late design transfer case with the rubber boot that attaches to the slip yoke on the drive shaft, measure from the slinger on the rear out-put of the transfer case (this will be the leading edge of the rubber boot) to the center of the universal joint at the rear differential. From this original dimension, we will be able to determine the required length of the drive shaft as an end result.

Early model transfer cases (usually 1994 and older)

If you have an early model transfer case, simply measure from the outermost lip of the rear out-put seal on the transfer case to the center of the joint at the differential end. From this original dimension, we will be able to determine the required length of the drive shaft as an end result.

Spline and Yoke Options

We offer a couple spline and yoke options for you to choose from. You should choose the options you prefer the shaft to have. The S spline is a conventional spline stub that will yield a safe, effective and usable stroke of 3”. The X spline is longer than the S spline. The X spline is cut for the full length of the spline stub. This gives a bit more than twice the contact area between the slip yoke and spline stub and a stroke of 4-1/2". This in and of itself will net more than twice the life on these two components.

With the XB configuration, we will use a heavy rubber boot which is banded down with stainless steel banding to seal all of the contaminates out and keep the grease in. The XC configuration uses the same slip yoke & spline stub but instead of using the rubber boot, we drill and tap the slip yoke for a grease fitting and use a dust cap which has convolutions that follow the spline stub for sealing. The XB is best for wet and dirty conditions. The XC is best for rocks and extreme wheeling.