XJ Rear Drive Shaft, Double Cardan

Rear drive shaft for Jeep XJ Cherokee. Double cardan type, also known as a CV. This is what you need if your Jeep is lifted and you are experiencing vibrations or other problems due to increased angles. Shaft will require a slip yoke eliminator. May also require axle shims to achieve the best results.

Tom Wood's XJ drive shafts are built using only the highest quality components. Key features listed below.

- 2" diameter .120" wall USA made DOM tube.

- Forged slip yoke.

- Greaseable CV center ball.

- Your choice between Tom Wood's exclusive Gold Seal greaseable universal joints or non-greaseable joints.

- Your choice of spline and slip yoke options, more about that here.

- Comes with new CV bolts with reduced head for ease of installation.

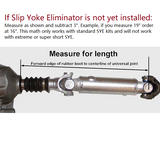

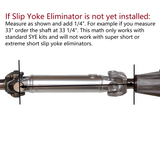

- Best of all every shaft is custom built to whatever length you need. So you can be sure that you will get the right thing the first time around. Jeep XJ rear drive shaft lengths vary a bit and we want to make sure you get the right thing. That is why we require a length measurement before building the shaft. Measuring is simple and easy. You can read more about how to measure in the link below.

IMPORTANT You must also measure the joint size where the shaft attaches to the rear axle. There are two possible joint sizes. Select the size that fits your yoke.

We recommend a new set of straps and bolts to securely attach your new drive shaft.